Production automation – the future of industrial plants in the era of Industry 4.0

Mayeryn

20 August 2025 • 13 min

Production automation – the foundation of competitiveness

Today, automation in production plants is not a choice, but a necessity. Industrial companies face increasing competition, rising labor costs, and customer demands for high quality and short lead times. Industrial automation not only reduces costs but also increases efficiency and workplace safety.

What are the benefits of production automation?

- Higher Efficiency and Cost Savings

Automated production lines can operate continuously, eliminating downtime and reducing raw material waste. While the initial investment can be high, the return on investment is rapid thanks to lower operating costs.

- Consistent Quality and Fewer Errors

Robotization in factories helps maintain consistent and high-quality products. Control systems eliminate variations, reducing complaints and building customer trust.

- Employee Safety

Robots and machines take over the most demanding and dangerous tasks. This reduces accidents and allows employees to focus on supervision and creative tasks.

- Real-Time Data

Modern automation systems provide managers with data on performance, energy consumption, and machine health. This is the basis for making sound business decisions.

Automation and Industry 4.0

Production automation is inextricably linked to the concept of Industry 4.0, or the smart factories of the future. It encompasses not only robotics but also:

- Internet of Things (IoT) – machines communicate with each other, transmitting data in real time,

- Artificial Intelligence – algorithms analyze information and predict potential failures,

- AR and VR – support machine training and maintenance,

- Eco-friendly production – process optimization saves energy and materials.

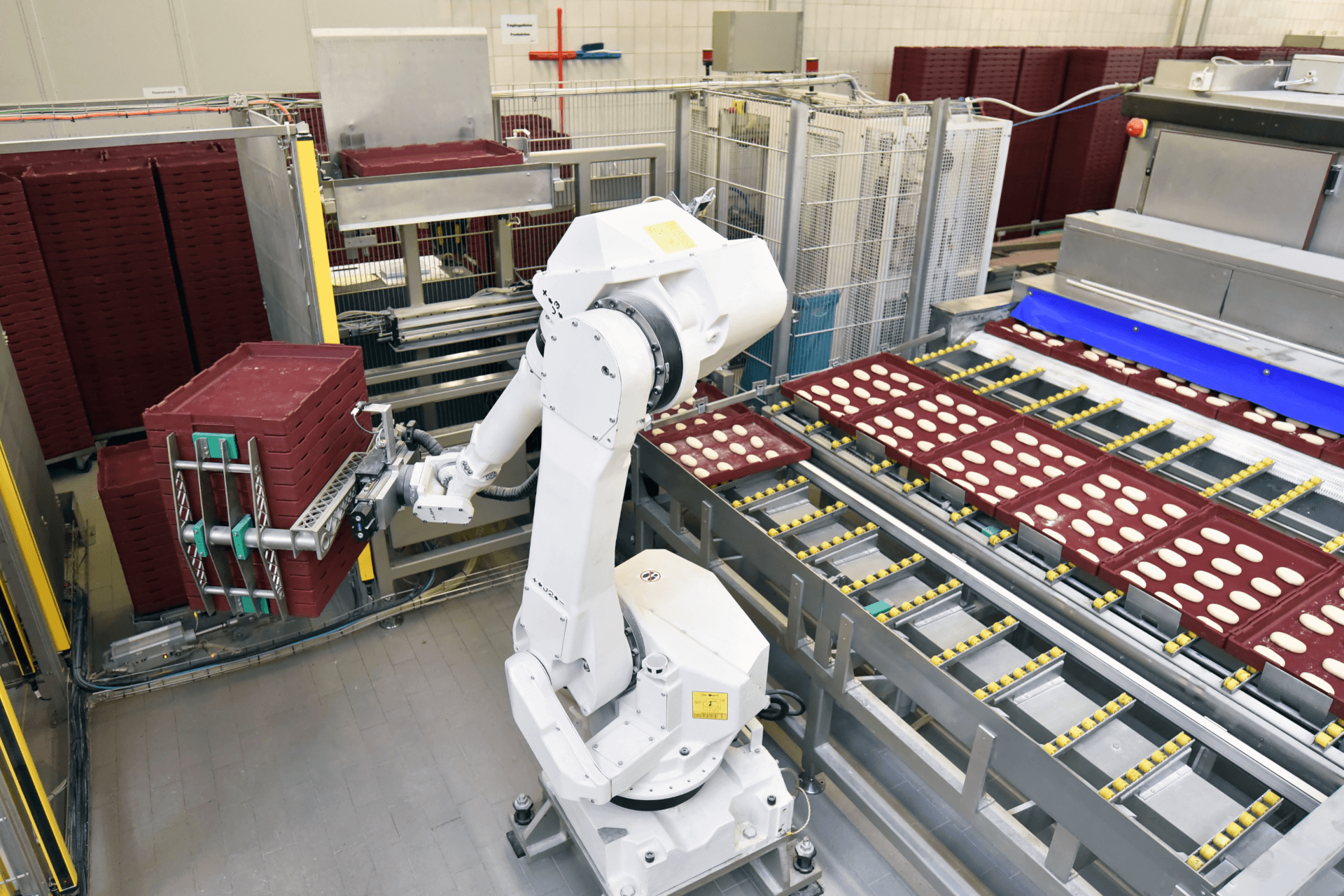

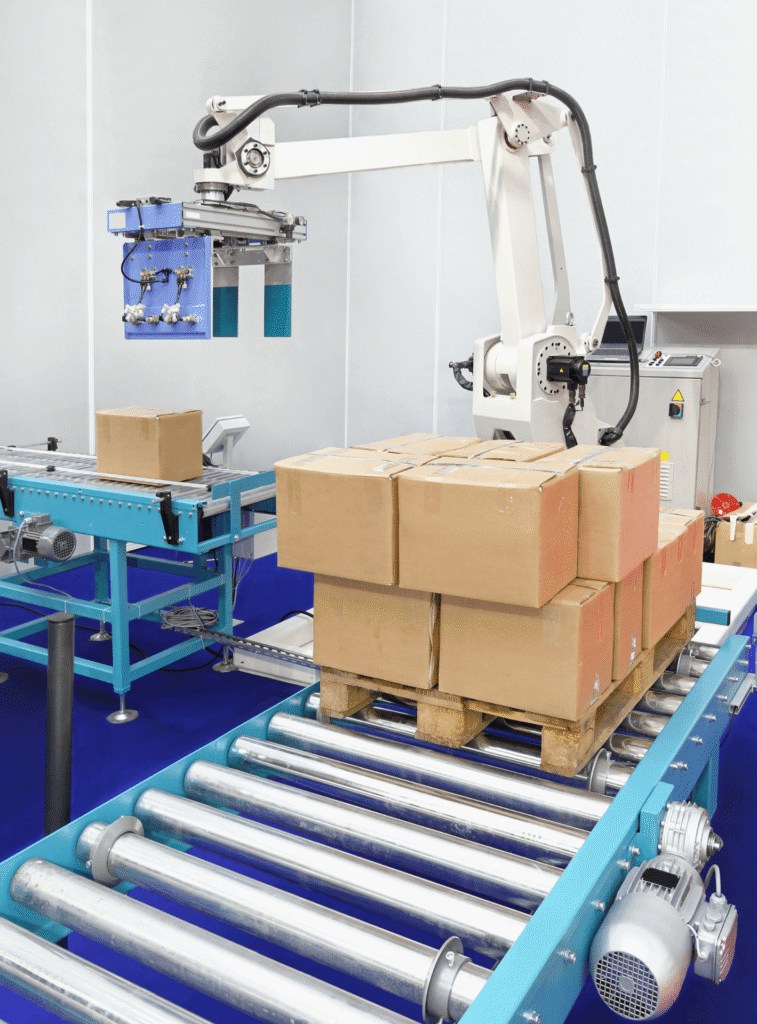

Examples of automation in various industries

- Automotive – welding robots and vision quality control systems,

- Food – automated packaging and sorting,

- Logistics and warehousing – automated warehouses and AGVs,

- Pharmaceuticals and chemicals – precise substance dosing and real-time quality control.

Challenges in implementing industrial automation

While the benefits are enormous, automation comes with some challenges:

- high investment costs,

- the need for employee training,

- the need for integration with existing ERP and CRM systems,

- cybersecurity in interconnected industrial networks.

The solution is to implement automation in stages and support a technology partner who will provide consulting and system integration.

Poland against the backdrop of the world – where are we?

The number of industrial robots in Poland is growing year by year. More and more companies are investing in production automation, but we still have a long way to go compared to leaders like Germany, Japan, and South Korea. This means enormous room for growth and opportunity for companies that choose robotization before their competitors.

Automation is an investment in the future

Industrial automation isn’t a cost, but an investment in the development, stability, and security of a company. It’s a tool that allows you to remain competitive in the global market, increase innovation, and prepare your facility for the challenges of the future.

Production automation and plant robotics are key elements of Industry 4.0. Companies that invest in modern technologies will gain a market advantage, operational security, and a stable position in the future.

If you’re wondering how to implement automation in your plant, contact us. We’ll help you plan and implement the investment step by step and calculate ROI and ROCE so you know whether the investment will pay off as you expect.